Today the brothers at AV Mechanical is here to dig up the sanitary connection so that a brand new PVC pipe can be connected instead of the old broken clay pipes.

|

|||

|

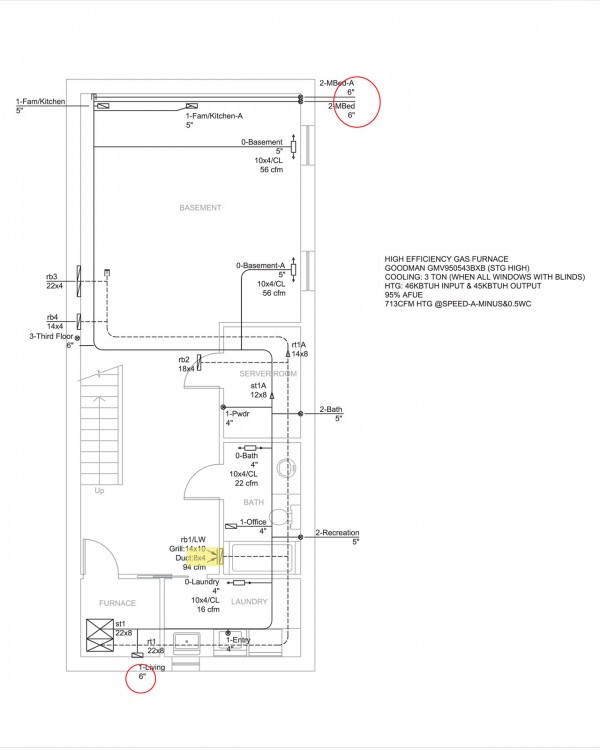

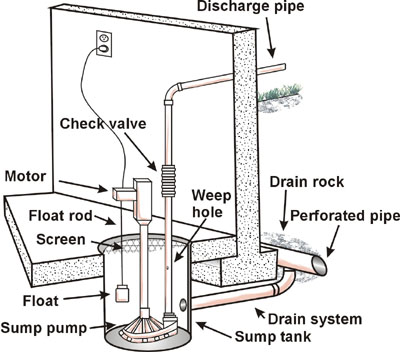

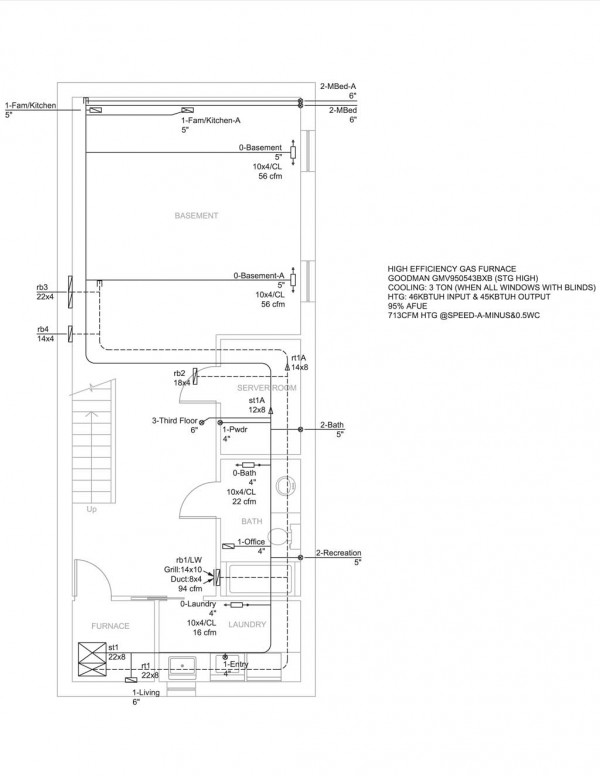

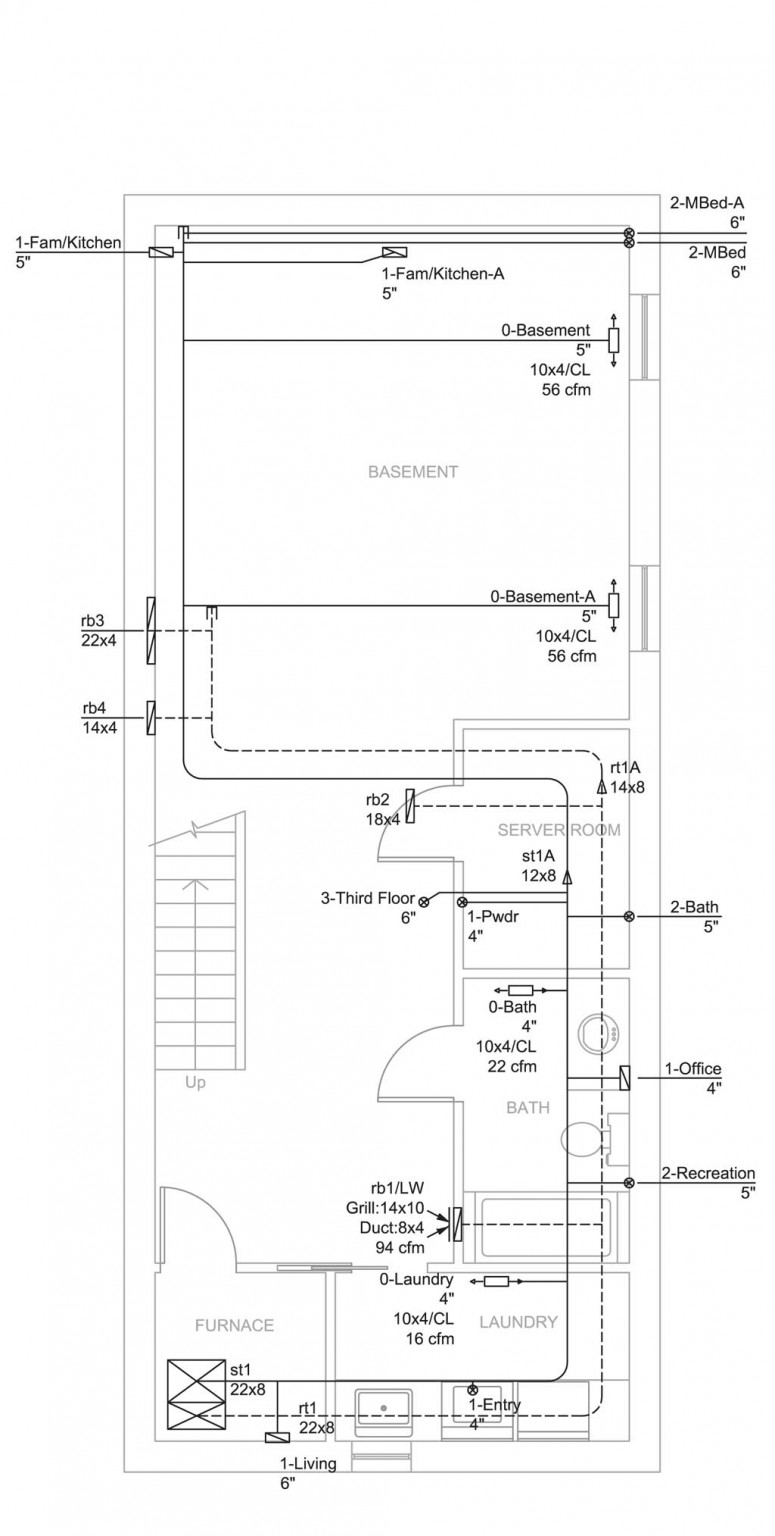

Well today’s officially day 1 of the plumbing connection. The plumber from AV Mechanical is scheduled to find the sanitary connection in the basement, dig out all the necessary trenches for the underground connections and connect to them all to the sanitary connection. However, nothing went as planned today. Remember these two clean out? Well from the look of it they are PVC and ABS pipes that connects to the sanitary line. We have assumed that the rest of the connections are also PVC. But look is deceiving. Trying to get the plumber started on the underground drain connections. But my basement is still full of ice from the winter snow that fell into the basement. This year, the average temperature is pretty low. It’s way past April and the ice in the basement still hasn’t fully melted. This is the west side of the basement. Here’s where most of the underground drain connections will be located. So I will have to melt all the ice here. There’s not a lot of ice, just a little bit on the ground. You can see that ice doesn’t even go up to the thermal blanket that’s on the footings. I was modeling the HVAC duct layout in 3D trying to make sure all the ducts will fit around the steel beams and inside the joists. I ran into some problem and a few changes will have to be made to the duct layout. The original design was based on an early drawing of where the steel beams will be located and was not revised after the structural steel shop drawings are finalized. It also never factored in the pluming runs that are necessary. In the basement, the biggest change here is to have the supply duct 3-Third Floor duct moved to the north wall instead of in the middle house. The duct is a 6″ duct and will not fit inside interior walls. And the original planned route for that duct has tons of obstacles due to structural steel in the upper floors. So go all the way up the north wall is the best solutions to conceal all the duct works inside the ceiling. The supply duct 0-Basement-A changed also have to be changes so that it comes in from the computer server room instead of from the north wall. Otherwise the duct will have to run below the joist because there’s a steel beam that runs vertical where it would have crossed the house. Today the job is to complete the back fill while tie up a few loose ends. First of all, as indicated in yesterday’s More plumbing issue post, the weeping tile will have to come into a sump pit inside the basement. So the Tony Cantalena and his crew from Lanor Disposal Inc came and dug up the north west corner of the foundation. They cut the weeping tile there, installed a T joint, and threaded the pipe under the footing into my basement. Today I was talking to the city inspector and he informed me that I am not allowed to have weeping tiles tied into the sewer. He indicated that weeping tile must be routed to an interior sump pit and a sump pump will pump the water out above grade. Now that’s yet another blow to my building project both for planning and for cost. Planning wise, I’ve already back filled most part of the house. Now excavator will have to come and dig up the north west corner again so that they can add a T joint on the weeper and then put a pipe under the footing into the house. Cost wise, I don’t know how much extra it will cost me to dig the hole again, but the sump pit and the pump and the extra plumbing will cost me around the neighbourhood of $1500. Today the excavation crew came back for back fill. The first thing they did was to dig out the sewer connection. So as it turns out, even though there’s a white and a black cleanout, I don’t actually have a separate storm connection and a sanitary connection. Instead I have a single sanitary connection. According to my plumber, the black cast iron pipe was used in the past as a breather. But the white PVC pipe somehow a cleanout going towards the house? This part confuses me a little bit. Having a little plumbing issue. First of all the water service pipe was buried by the excavator. When I eventually dug it up based on my photos, it is discovered that it was an really old 1/2″ lead pipe. So I have decided not to reused the existing water service connection and request a new connection from the city. However, this means extra cost. As of 2013, City of Toronto charges $2700 for a new 3/4″ connection and $3111 for a new 1″ connection. I’m probably going to apply for a new 1″ connection since there’s not that much difference and it’s probably better to be prepared for the future. But none the less, it’s an extra $3000 that I didn’t want to spend. Here’s a photo with an arrow pointing at the 1/2″ lead water service connection. One of the things we were missing for building permit application last Wednesday was signed Schedule 1 Designer Information from the HVAC designer and signature on the drawing and the heat loss calculation. We informed Haibo Chen from Fulford Supply that we needed the form from him and I’ve also sent him a few minor revisions. Mr Chen came through on Monday with the files. We’ve also got signed drawings from Ben Mashhadi of ABM Engineering. So finally I think we have everything we need to get the building permit application through. Here’s the final HVAC duct layout. Not a lot has been changed, just some minor relocation. We’ve done most of the work on the structural engineering on the placement of the steel beams to make the duct layout work. Basement duct layout: My house design calls for a ductless heat pump that will provide the main cooling and heating with a backup heating via standard forced air furnace. The reason for the need for a backup heating source is that most air-to-air heat pump will stop working by -15°C. Now in Toronto, there are not many days (nor that many hours during the day) in the winter where temperature will fall below -15°C. However, a backup heating source is still necessary to ensure that we are not in the cold when the heat pump had to be turned off. I’ve also called for separate ducts for a Heat Recover Ventilation because that’s the right way to bring fresh air into a relative air tight house. For the HVAC design we have contracted Haibo Chen from Fulford Supply. Mr Chen told me that in Toronto the design temperature is -20°C. Because the air-to-air heat pump will no longer be working at -15°C, so even though I consider the furnace as the back source, during the design stage for building permit, it is probably better to just have the furnace as the main source of heat. Then once I have all the heat loss information, I can simply choose the heat pump to match the heat loss numbers. The total charge is $750 for the furnace duct design and heat loss calculation, and $200 for HRV calculation and design. Mr Chen is very prompt with the work. We started the work on April 11 and he provided his preliminary drawings on April 19, one week after the work started. Here’s the furnace duct design. Basement: |

|||

|

Copyright © 2024 Viper Info-Tech Solutions, Inc. All Rights Reserved. (Posts RSS | Comments RSS) Powered by WordPress & Atahualpa |

|||